RÉSUMÉ DU PROJET

RÉSUMÉ DU PROJET

Le projet Dumont détenu à 100% par Magneto Investments L.P. est l’un des plus grands gisements de sulfures de nickel non développé prêt à démarrer et ayant reçu ses principales autorisations environnementales.

Le projet Dumont est un projet à grande échelle situé à 25 km à l’ouest de la ville d’Amos dans le camp minier bien établi de l’Abitibi au Québec, une province canadienne favorable à l’industrie minière.

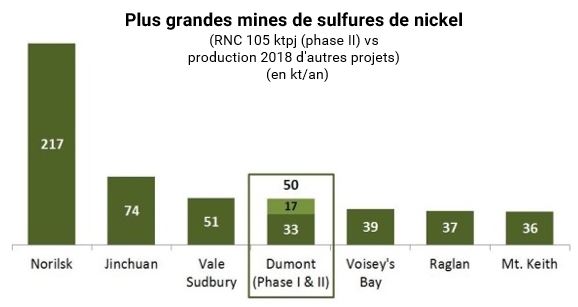

Une fois en exploitation, il occuperait le cinquième rang parmi les plus grandes mines de sulfures de nickel du monde, avec une production annuelle moyenne de 39 kt pour une durée de vie de plus de 30 ans. Il serait devancé uniquement par les opérations minières de Norilsk (Russie), Jinchuan (Chine) et Sudbury (Ontario, Canada).

La construction et l’exploitation de la mine et des installations de traitement seront facilitées par la présence d’excellentes infrastructures, notamment les réseaux routier et ferroviaire et un approvisionnement en hydroélectricité permettant de réduire l’empreinte environnementale du projet.

Le minerai extrait à Dumont sera transformé sur le site en utilisant des méthodes conventionnelles et éprouvées afin de produire un concentré à haute teneur en nickel. Ce concentré sera ensuite envoyé à l’extérieur du site minier pour recevoir une transformation additionnelle. Ainsi en opération, la mine produira du nickel pendant plus de 30 ans.

Les roches stériles et les résidus miniers ne seront pas générateurs d’acides, ce qui constitue également un avantage indéniable sur le plan environnemental.

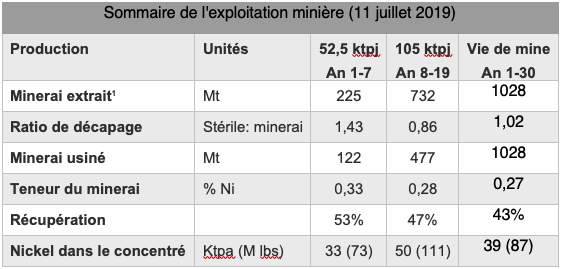

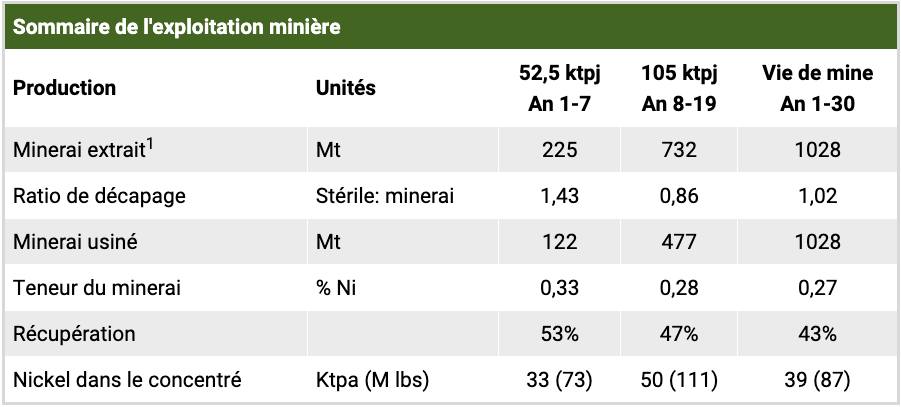

EXPLOITATION MINIÈRE

Le gisement Nion contient près de 6,1 milliards de livres de nickel dans la catégorie des réserves prouvées et probables (1 028 millions de tonnes en réserves prouvées et probables à 0,27 % nickel).

¹Les totaux incluent le prédécapage de 42 Mt, comprenant 13 millions de tonnes de minerai, avant le début de la production de l’usine.

TRAITEMENT DU MINERAI

Le minerai extrait à Nion sera traité et transformé sur le site minier pour produire un concentré à haute teneur de nickel (29%). Les technologies employées dans le concentrateur sont des technologies courantes qui ont fait leurs preuves.

Le concentré produit sera ensuite acheminé hors du site pour un traitement additionnel afin d’en faire un produit répondant aux clients potentiels.

Capacité de traitement du concentrateur

Le concentrateur aura au démarrage une capacité de traitement de 52,5 kt/j de minerai traité. À l’an 7, une expansion portera ce taux à 105 kt/j.

Les principales étapes de transformation au concentrateur sont :

- Broyage du minerai

- Enlèvement des particules fines (déschlammage)

- Flottation de dégrossissage et de purification des fines

- Flottation de dégrossissage, épuisement et purification des sulfures

- Séparation magnétique, rebroyage et récupération de l’awaruite

- Filtration du concentré Spécificités du concentré de Nion Le concentré produit à Nion sera une poudre métallique avec une teneur élevée en nickel de 29%. Il contiendra également 0,9% de Cobalt, 1,4g/t de Platine et 3g/t de Palladium.

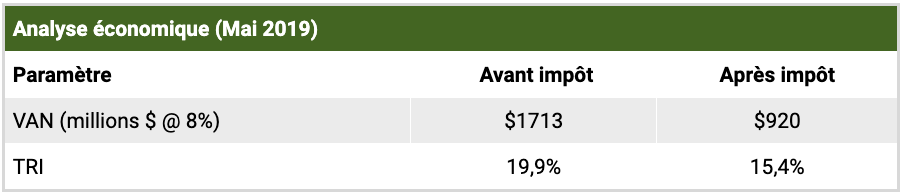

ÉCONOMIE DU PROJET

1. Production de Dumont basée sur la phase II d’expansion à l’année 7.

Le gisement Dumont contient près de 6,1 milliards de livres de nickel dans la catégorie des réserves prouvées et probables (1 028 millions de tonnes en réserves prouvées et probables à 0,27 % nickel) et 9,75 milliards de livres de nickel dans la catégorie des ressources mesurées et indiquées (372 millions de tonnes en ressources mesurées à 0,28 % nickel et 1,29 milliard de tonnes en ressources indiquées à 0,26 % nickel).

La catégorie des ressources présumées compte environ 2,9 milliards de livres de nickel (500 millions de tonnes à 0,26 % nickel).

1.Les totaux incluent le pré-décapage de 42 Mt, comprenant 13 millions de tonnes de minerai, avant le début de la production de l’usine.

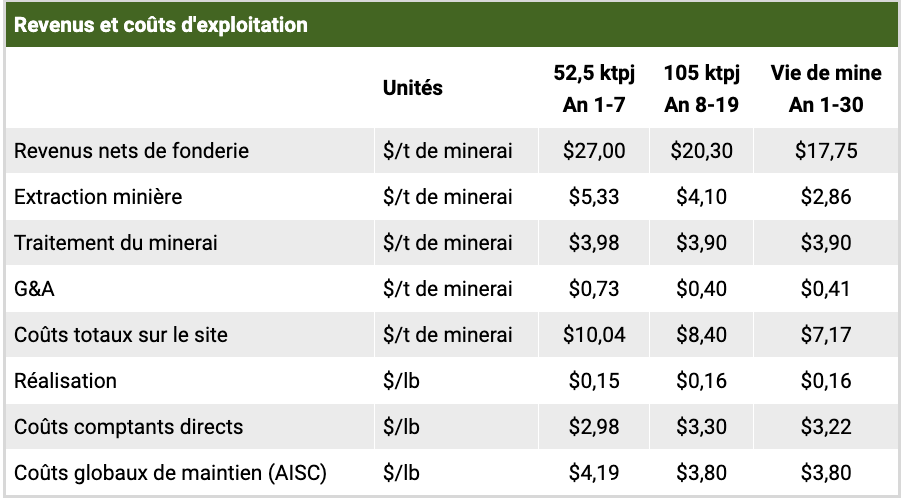

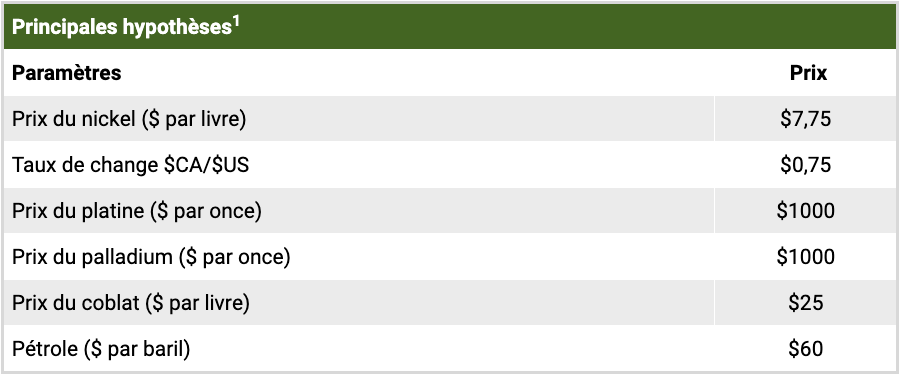

1. Les hypothèses de prix pour le nickel sont basées sur la moyenne des prévisions pour un groupe de deux analystes externes indépendants de l’industrie du nickel. L’hypothèse de prix pour le cobalt, le platine et le palladium sont basées sur les prévisions de Consensus Economics Inc.

PROJET DUMONT

RÉSUMÉ DU PROJET

Le projet Dumont Nickel est l’un des plus grands gisements de sulfures de nickel non développé, prêt à démarrer et ayant reçu ses principales autorisations environnementales.

Le projet Dumont Nickel est un projet à grande échelle situé à 25 km à l’ouest de la ville d’Amos dans la région minière bien établi de l’Abitibi au Québec. La réserve minière est établie à plus de 1 milliard de tonnes avec une teneur de 0.27% de nickel et 107 ppm de cobalt.

Une fois en exploitation, cette réserve assurera une production annuelle moyenne de 39 kt de nickel pour une durée de vie de plus de 30 ans, créant environ 500 emplois qualifiés et bien rémunérés. Cette production pourra fournir assez de nickel pour construire environ 780 000 véhicules électriques par années.

Le Projet Dumont Nickel a le potentiel d’être la clé de l’approvisionnement en nickel pour la filière batterie québécoise.

La construction et l’exploitation de la mine et des installations de traitement seront facilitées par la présence d’excellentes infrastructures, notamment les réseaux routier et ferroviaire et un approvisionnement en hydroélectricité permettant de réduire l’empreinte environnementale du projet. Les roches stériles et les résidus miniers ne seront pas générateurs d’acides, ce qui constitue également un avantage indéniable sur le plan environnemental. L’empreinte carbone du projet est d’avantage réduite par la capacité des résidus miniers à séquestrer le carbone de façon spontanée.

Avec des dépenses en capitaux initiales de 2,0$ milliards et des retombées économiques annuelles de l’ordre de 300 millions de dollars en pièces et services, le projet Dumont Nickel sera bénéfique autant pour l’économie locale que pour celle du Québec en entier.

Le Projet Dumont en bref

Une exploitation minière respectueuse de l’environnement et bénéfique pour l’économie du Québec, avec les meilleures références ESG.

Une production moyenne de 39 000 tonnes par année de nickel sous forme de concentré de sulfure à un coût d’exploitation dans le deuxième quartile

Pourra fournir du nickel et du cobalt pour environ 780 000 véhicules électriques par année. Les investisseurs s’intéressent à Dumont pour son extraction responsable du nickel à faible empreinte carbone

Une mine avec une longue durée de vie de 30 ans et des bénéfices durables pour les communautés, dont la création d’une moyenne d’environ 500 emplois grâce à un investissement de 2,0$ milliards

Acceptabilité sociale : engagement continu avec les communautés hôtes et une entente sur les répercussions et les avantages avec ses partenaires de la Première Nation Abitibiwinni

Le Projet Dumont a déjà fait l’objet d’une analyse du BAPE et détient son certificat d’autorisation.

Décision de mise en chantier (construction) en 2025 avec un démarrage de la production de nickel prévu au deuxième trimestre 2028

La chaîne d'approvisionnement des batteries

Le Projet Dumont jouera un rôle essentiel dans l’approvisionnement en matières premières de nickel et de cobalt

Projet Dumont: Faible empreinte carbone

Dumont sera l'une des exploitations de nickel à empreinte carbone la plus faible au monde

- Dumont générera seulement 2,1 kg eq CO2 par kg de nickel (Scope 1 et 2) grâce à l'énergie renouvelable du Québec

- Augmentation de l'électrification de la mine pour réduire la consommation de diesel et les émissions de GES d'environ 1/3 (Trolley)

- Les émissions de GES directement liées aux activités du site (Scope 1) sont compensées par le potentiel de séquestration des résidus et des stériles

Courbe CO2E de l’industrie du nickel 2035E

Illustration de la séquestration du carbone dans les résidus et les stériles

Progression de la valorisation du concentré

- Échantillonnage en vrac (janvier 2023) sur le site du projet Dumont et traitement de la roche extraite pour produire du concentré de nickel.

- Résultat d'essais en laboratoire : la lixiviation du concentré permet une bonne récupération du nickel et du cobalt (>97%) et de produire un précipité d'hydroxyde mixte (MHP) contenant plus de 45% de nickel et de cobalt, taux suffisant pour alimenter la filière batterie.

- Ces travaux furent réalisés en 2020-2021 avec le soutien des programmes Innovation du MEIE et PARIDM du MRNF.

- Poursuite des travaux en 2024 par NiVolt pour appuyer une étude de faisabilité pour la commercialisation du procédé.

- NiVolt évalue des sites au Québec qui pourraient accueillir une nouvelle installation de transformation.

Contexte favorable au projet Dumont

- La transition énergétique (utilisation de technologie émettant moins de gaz à effet de serre) s’accompagne d’une augmentation de la demande des minéraux stratégiques dont font partie le nickel, le cobalt, le lithium et le graphite.

- Les projections d’utilisation du nickel au niveau mondial prévoient que la part du nickel dédiée batterie doublera entre 2021 et 2040.

DOCUMENTATION TECHNIQUE

Rapport technique sur le projet nickélifère Nion

Rapport technique pour Nion, Bernier, S. et Leuangthong, Appendices

Rapport technique pour Nion, Marois, J. et Mineral Solutions, Appendices

Rapport technique pour Nion, Patsius et Imeson, Appendices

Rapport technique pour Nion, Verret et Imeson, Appendices